2011 Brema Vektor 15 - 13

Specifications

| Manufacturer | Brema |

| Model | Vektor 15 - 13 |

| Year | 2011 |

| Stock Number | MHH005 |

Description

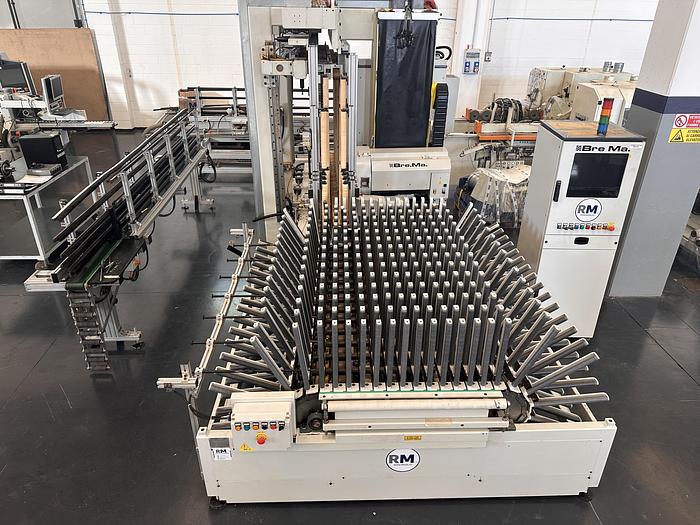

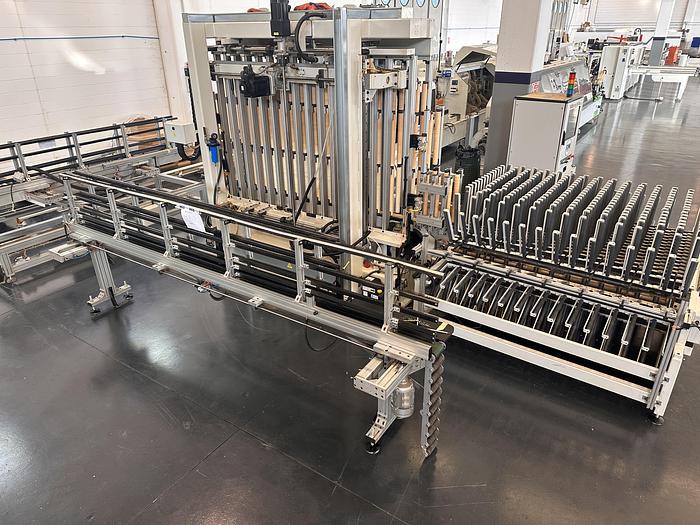

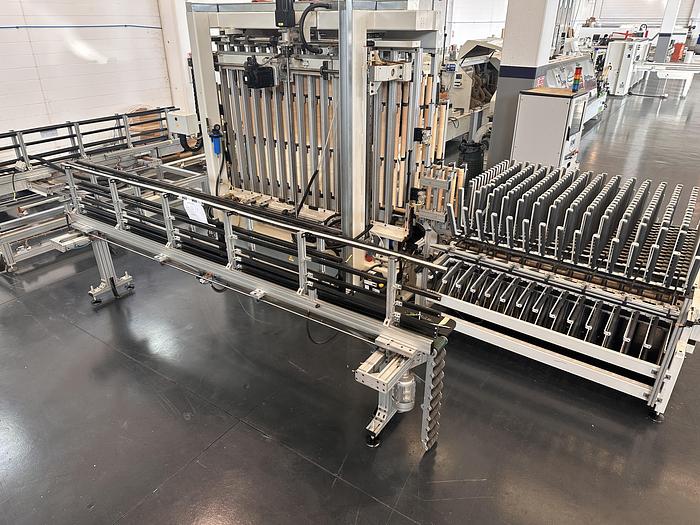

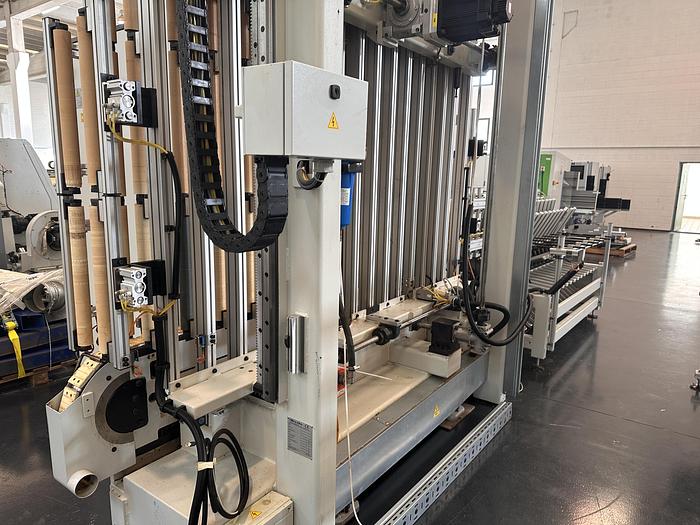

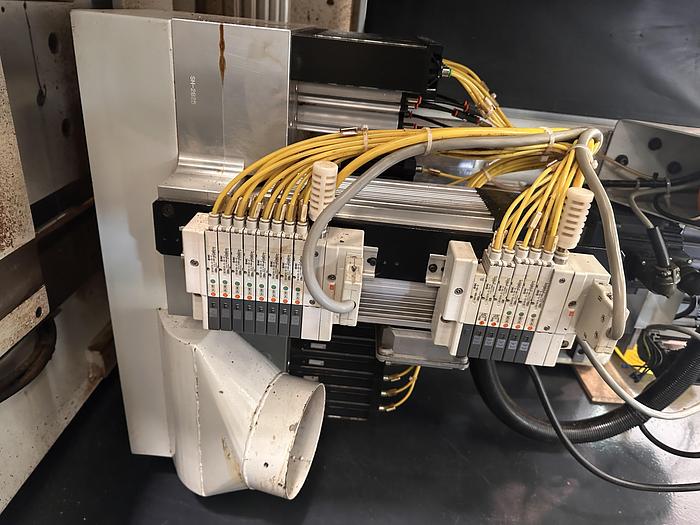

Highly flexible vertical machining center for milling, drilling and cutting. The BREMA patent for processing vertically, allows this series of machines to be the most flexible and productive machine par excellence to a very high quality level. Furthermore, the automatic return / rotation system of the panel makes it fully automated. Possibility of working in height up to 1300 mm, working on all 6 sides of the panel. Working dimensions: * length 300 - 2500 mm * height 60 - 1300 mm * thickness 10 - 80 mm * max weight 50 kg Machine programming and control system with PC - TPA Albatros software. Programming editor with a high-level software interface allows you to program the machine easily and intuitively and also allows: * linear, circular and helical interpolation * double zero reading * mirror program management * optimizer for revolver tool diameter * optimizer for independent spindle diameter * DXF file conversion (geometric conversion) * import of work lists in ASCII format * extra key for programming from the office * gun barcode reader * 17” LCD monitor * Windows 7 professional operating system Panel introduction and handling via motorized vertical comb transfer with rollers. The photocells and the CN program guarantee the introduction of one or more panels in sequence via selector. Panel height reading system consisting of an independent axis able to read the panel height before getting into the car. Size reading tolerance +\- 0.15 mm. In case the tolerance is exceeded a message will inform the operator and the machine will stop the operation in progress. Panel thickness reading system using a mechanical feeler Chain - X axis - Bre.Ma patent double section with laser photocells able to read the reference zero of the panel before carrying out the work. The double section allows you to carry out machining on the lower side of the panel thus having the possibility of work the panel on 6 sides. Brushless motors with programmable speed regulation by NC. Drilling unit with independent vertical and horizontal spindles Upper revolver milling group with 10 positions and tool change controlled by NC. Automatic lubrication 180° panel translation and rotation system Movement and rotation system of the panel arriving from the machine which allows unloading or rotation of the panel and the return to the machine for machining on both surfaces of the panel. The system consists of a vertical transfer with rubber pressure rollers for receiving the panel from machine. The 180° rotation system allows the panel to rotate around its axis and return to machining. Unloading system with motorized belt